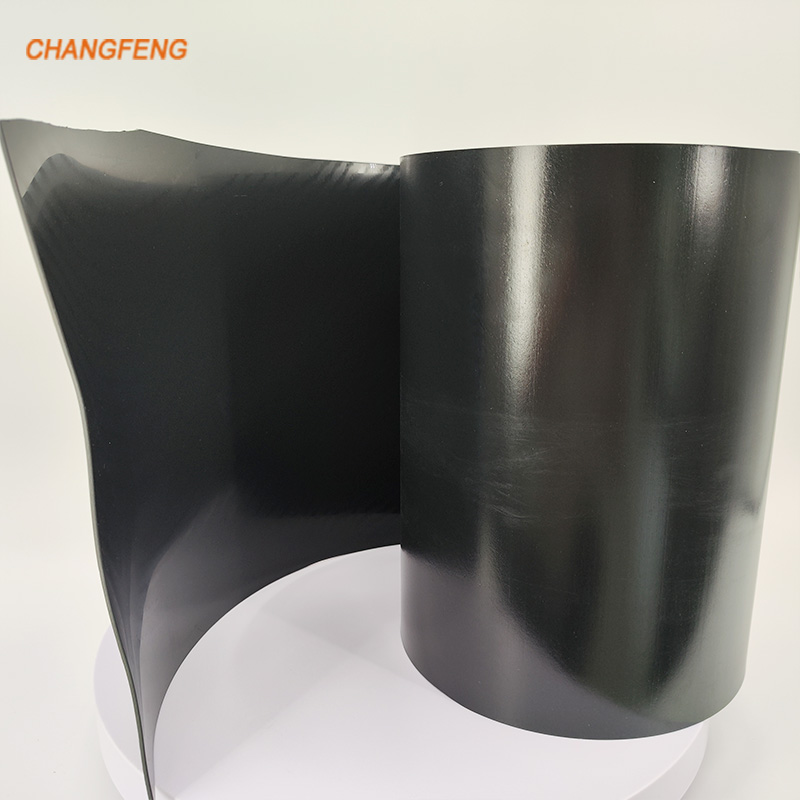

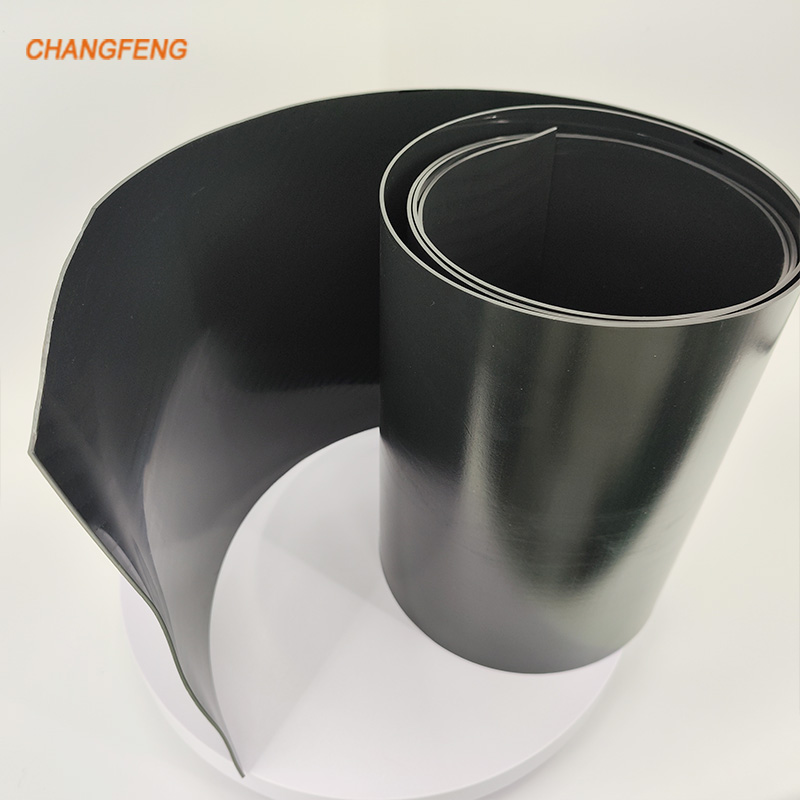

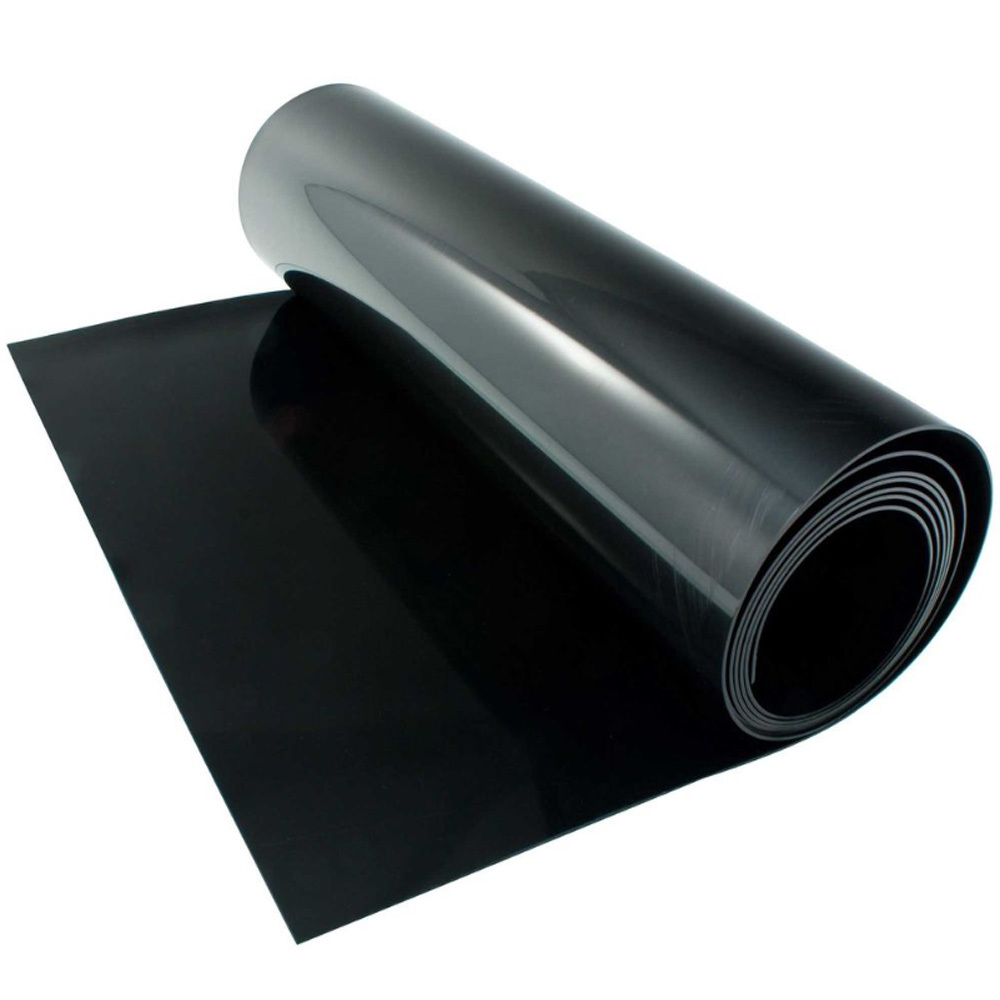

Products Description

| Name; geomembrane |

| Length; 1-6m |

| Thickness; 0.3 -2 mm |

| Material; HDPE, LDPE, PVC, LLDPE |

| Color; Black, white, blue, customized products can be supported according to customer needs |

Geomembranes, also known as geosynthetic membranes, are essential components in various industries, including waste containment, water management, aquaculture, energy, mining, and civil engineering. They provide reliable barriers against liquid and gas migration, ensuring environmental protection and resource conservation.

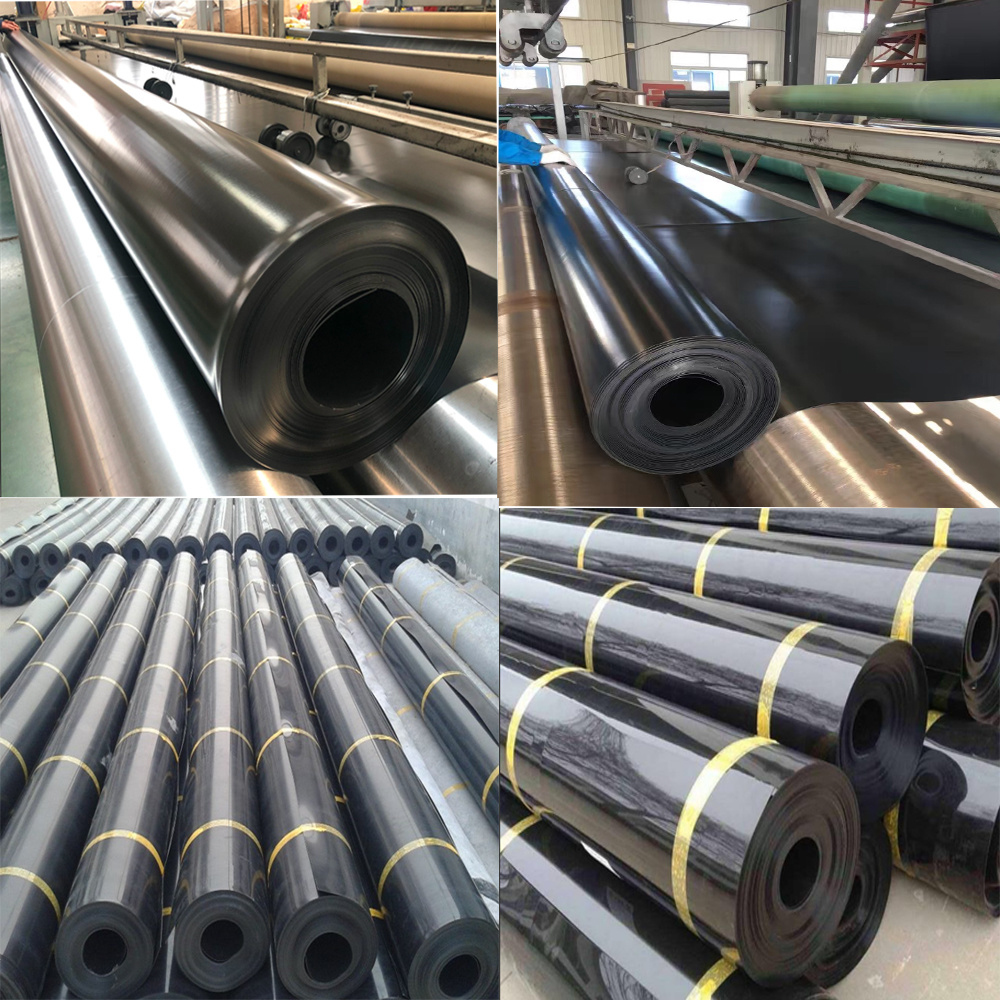

Material and Production:

Our geomembranes are manufactured from high-grade polyethylene raw materials, enhanced with carbon black, antioxidants, and UV-resistant additives. Utilizing state-of-the-art automated production lines and advanced pressing technology, we guarantee superior quality and durability.

|  |  |  |  |

- Irrigation ponds, canals, ditches & water reservoirs

- Mining heap leach & slag tailing ponds

- Golf course & decorative ponds

- Landfill cells, covers, & caps

- Wastewater lagoons

- Secondary containment cells/systems

- Liquid containment

- Environmental containment

- Soil Remediation

|  |

|  |  |

Properties | Test Method | GMSH050 | GMSH075 | GMSH100 | GMSH150 | GMSH200 |

■ Thickness | ASTM D5199 | 0.50 mm | 0.75 mm | 1.00 mm | 1.50 mm | 2.00 mm |

■ Density | ASTM D1505 | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc |

Tensile Properties |

|

|

|

|

|

|

■ Yield strength ■ Break strength ■ Yield elongation ■ Break elongation | ASTM D6693 Type IV

| 7 kN/m 13 kN/m 12% 700% | 11 kN/m 20 kN/m 12% 700% | 15 kN/m 27 kN/m 12% 700% | 22 kN/m 40 kN/m 12% 700% | 29 kN/m 53 kN/m 12% 700% |

■ Tear Resistance | ASTM D1004 | 62 N | 93 N | 125 N | 187 N | 249 N |

■ Puncture Resistance | ASTM D4833 | 160 N | 240 N | 320 N | 480 N | 640 N |

■ Stress Crack Resistance | ASTM D5397 | 500 hrs | 500 hrs | 500 hrs | 500 hrs | 500 hrs |

■ Carbon Black Content | ASTM D1603 | 2.0% | 2.0% | 2.0% | 2.0% | 2.0% |

■ Carbon Black Dispersion | ASTM D5596 | For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 | ||||

■ Oxidative Induction Time (OIT) | ASTM D3895 | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. |

■ UV Resistance High Pressure OIT retained after 1600hrs |

ASTM D5885 |

50% |

50% |

50% |

50% |

50% |

Dimensions |

|

|

|

|

|

|

■ Roll Width (m) |

| 7 | 7 | 7 | 7 | 7 |

■ Roll Length (m) |

| 420 | 280 | 210 | 140 | 105 |

|  |