Products Description

| Name; geomembrane |

| Length; 1-6m |

| Thickness; 0.3 -2 mm |

| Material; HDPE, LDPE, PVC, LLDPE |

| Color; Black, white, blue, customized products can be supported according to customer needs |

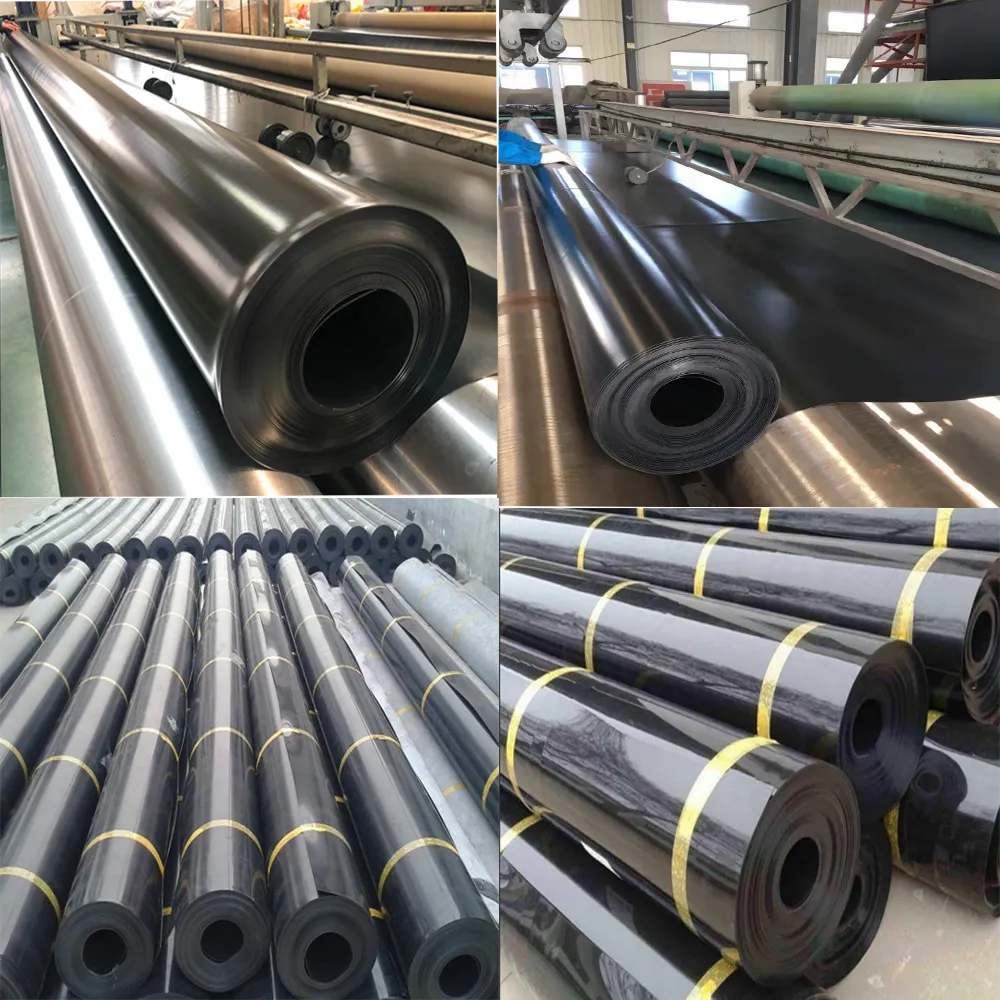

Blowing movie is a usually used plastic processing technique for producing skinny movie substances such as geosynthetic motion pictures and packaging films. The following is the manufacturing manner of blown geomembrane

Raw cloth injection: Inject plastic particles or granular substances into the hopper of the blowing computing device thru the equipment.

Heating and melting: The uncooked cloth is heated and melted to emerge as a flowing state.

Extrusion film: The molten uncooked fabric is extruded from the die head via an extruder to shape a skinny movie sheet.

Cooling and curing: The movie is cooled and cured through a cooling curler to make sure its balance and uniformity.

|  |

|  |  |

Roll up and roll up: Slice and roll up the cooled and solidified geotextile to shape a completed roll.

Quality inspection: Conduct nice inspection on the geomembrane, which include overall performance checks such as thickness, tensile strength, and put on resistance.

Packaging factory: Qualified geosynthetic movie is packaged and prepared to be furnished to the market or customers.

Blowing movie is an environment friendly manufacturing technique that can produce extremely good geosynthetic movie products. I hope the above data can be useful to you. If you have any different questions, please sense free to elevate them at any time.

Properties | Test Method | GMSH050 | GMSH075 | GMSH100 | GMSH150 | GMSH200 |

■ Thickness | ASTM D5199 | 0.50 mm | 0.75 mm | 1.00 mm | 1.50 mm | 2.00 mm |

■ Density | ASTM D1505 | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc |

Tensile Properties |

|

|

|

|

|

|

■ Yield strength ■ Break strength ■ Yield elongation ■ Break elongation | ASTM D6693 Type IV

| 7 kN/m 13 kN/m 12% 700% | 11 kN/m 20 kN/m 12% 700% | 15 kN/m 27 kN/m 12% 700% | 22 kN/m 40 kN/m 12% 700% | 29 kN/m 53 kN/m 12% 700% |

■ Tear Resistance | ASTM D1004 | 62 N | 93 N | 125 N | 187 N | 249 N |

■ Puncture Resistance | ASTM D4833 | 160 N | 240 N | 320 N | 480 N | 640 N |

■ Stress Crack Resistance | ASTM D5397 | 500 hrs | 500 hrs | 500 hrs | 500 hrs | 500 hrs |

■ Carbon Black Content | ASTM D1603 | 2.0% | 2.0% | 2.0% | 2.0% | 2.0% |

■ Carbon Black Dispersion | ASTM D5596 | For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 | ||||

■ Oxidative Induction Time (OIT) | ASTM D3895 | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. |

■ UV Resistance High Pressure OIT retained after 1600hrs |

ASTM D5885 |

50% |

50% |

50% |

50% |

50% |

Dimensions |

|

|

|

|

|

|

■ Roll Width (m) |

| 7 | 7 | 7 | 7 | 7 |

■ Roll Length (m) |

| 420 | 280 | 210 | 140 | 105 |

|  |