Products Description

| Name; geomembrane |

| Length; 1-6m |

| Thickness; 0.3 -2 mm |

| Material; HDPE, LDPE, PVC, LLDPE |

| Color; Black, white, blue, customized products can be supported according to customer needs |

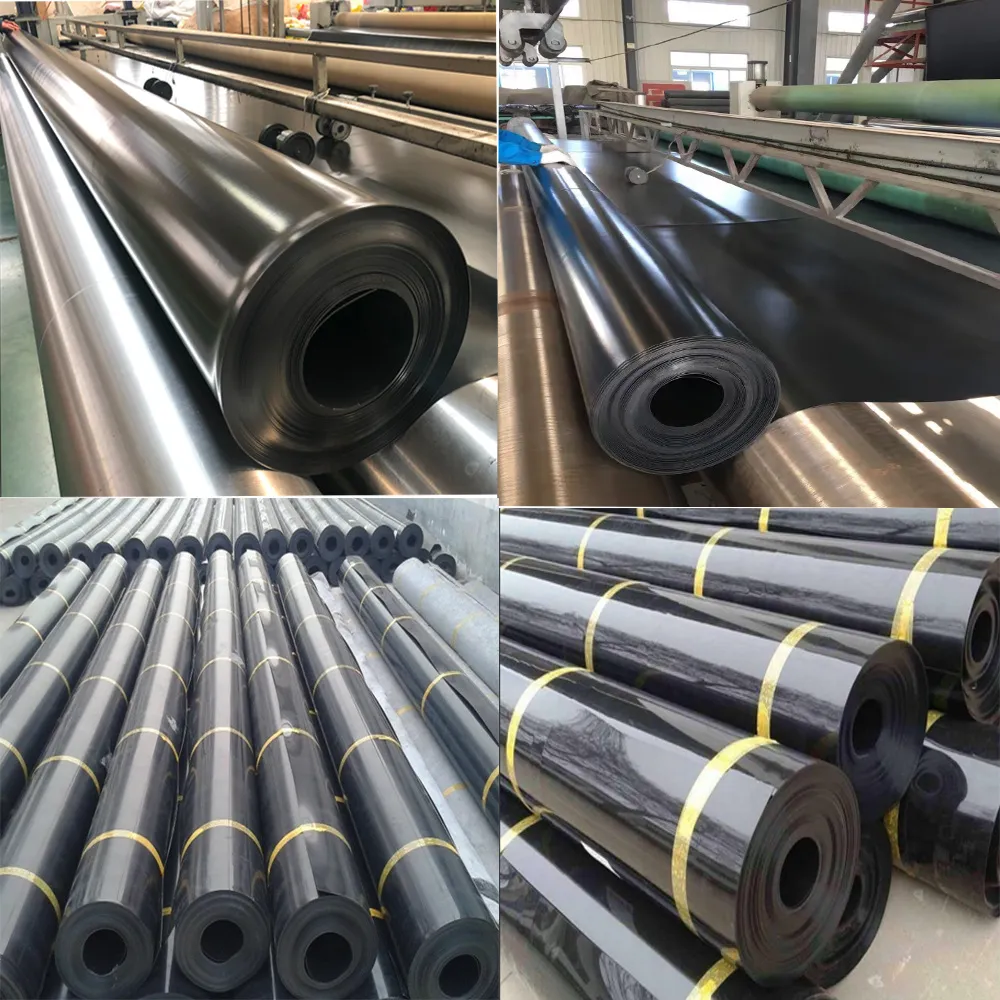

HDPE geomembrane is a geomembrane product that types a matte floor by using nitrogen stress jetting on the groundwork of a sleek geomembrane. This method is the solely way to produce a matte geomembrane barring appreciably decreasing any of its bodily properties. The geomembrane product is made of excessive pleasant excessive density polyethylene material, which is made of a mixture of about 97.5% polymer, 2.5% carbon black, a hint quantity of antioxidant and warmth stabilizer. The resin used in the manufacturing procedure is designed for The uncooked polyethylene resin uncooked cloth really organized via the geomembrane application.

Product performance:Perfect anti-seepage, high obstruction, high puncture-resistance, excellent performance of chemical erosion resistance, good lasting quality, no pollution, easy to splice and construct.Product main use:Highways, irrigation works, lake dam, shore protection project, railways, tunnels, landfill waste site, sea-farming, salt pond, sewage treatment works, golf-links, etc.

|  |

|  |  |

Properties | Test Method | GMSH050 | GMSH075 | GMSH100 | GMSH150 | GMSH200 |

■ Thickness | ASTM D5199 | 0.50 mm | 0.75 mm | 1.00 mm | 1.50 mm | 2.00 mm |

■ Density | ASTM D1505 | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc |

Tensile Properties |

|

|

|

|

|

|

■ Yield strength ■ Break strength ■ Yield elongation ■ Break elongation | ASTM D6693 Type IV

| 7 kN/m 13 kN/m 12% 700% | 11 kN/m 20 kN/m 12% 700% | 15 kN/m 27 kN/m 12% 700% | 22 kN/m 40 kN/m 12% 700% | 29 kN/m 53 kN/m 12% 700% |

■ Tear Resistance | ASTM D1004 | 62 N | 93 N | 125 N | 187 N | 249 N |

■ Puncture Resistance | ASTM D4833 | 160 N | 240 N | 320 N | 480 N | 640 N |

■ Stress Crack Resistance | ASTM D5397 | 500 hrs | 500 hrs | 500 hrs | 500 hrs | 500 hrs |

■ Carbon Black Content | ASTM D1603 | 2.0% | 2.0% | 2.0% | 2.0% | 2.0% |

■ Carbon Black Dispersion | ASTM D5596 | For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 | ||||

■ Oxidative Induction Time (OIT) | ASTM D3895 | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. |

■ UV Resistance High Pressure OIT retained after 1600hrs |

ASTM D5885 |

50% |

50% |

50% |

50% |

50% |

Dimensions |

|

|

|

|

|

|

■ Roll Width (m) |

| 7 | 7 | 7 | 7 | 7 |

■ Roll Length (m) |

| 420 | 280 | 210 | 140 | 105 |

|  |