Products Description

| Name; geomembrane |

| Length; 1-6m |

| Thickness; 0.3 -2 mm |

| Material; HDPE, LDPE, PVC, LLDPE |

| Color; Black, white, blue, customized products can be supported according to customer needs |

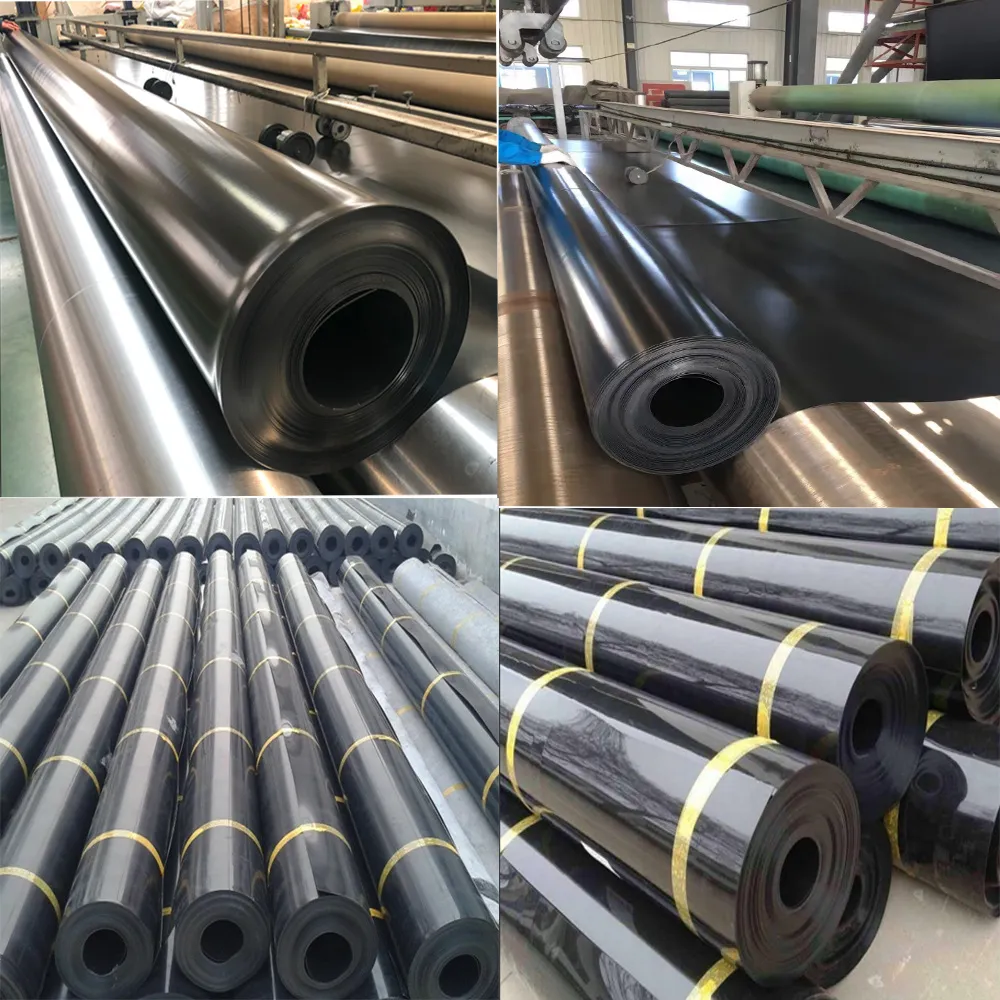

HDPE/LLDPE smooth/textured geotextile anti-seepage movie is produced with the aid of Italian automated geotextile manufacturing equipment, uniform plasticization, and co extrusion. Made from magnificent unique polyethylene resin and imported carbon black from Cabot.Geomembrane merchandise shield the Earth from the have an effect on of waste and pollutants, guard investments, and make certain the integrity and sustainability of crucial infrastructure in harsh environments. We have information in all geosynthetic substances and are dedicated to non-stop innovation. Our imaginative and prescient is to promote the improvement of the geosynthetic substances industry, enhance enterprise standards, and create extra reliable, stronger, air pollution resistant, and ubiquitous products.

1. Excellent flexibility, impermeability, elongation, and put on resistance;2. It has excellent isolation and puncture resistance;3. No chemical pollution;4. It is resistant to acid, alkali, and a number of chemical substances, with desirable dimensional steadiness and adhesion, making it handy to construct.

5. Good adaptability to excessive and low temperature, non-toxicity, lengthy provider life.6. Good waterproof, drainage, anti-seepage and damp proof effects.7. Complete width and thickness specifications, low price and handy installation.

|  |

|  |  |

Properties | Test Method | GMSH050 | GMSH075 | GMSH100 | GMSH150 | GMSH200 |

■ Thickness | ASTM D5199 | 0.50 mm | 0.75 mm | 1.00 mm | 1.50 mm | 2.00 mm |

■ Density | ASTM D1505 | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc |

Tensile Properties |

|

|

|

|

|

|

■ Yield strength ■ Break strength ■ Yield elongation ■ Break elongation | ASTM D6693 Type IV

| 7 kN/m 13 kN/m 12% 700% | 11 kN/m 20 kN/m 12% 700% | 15 kN/m 27 kN/m 12% 700% | 22 kN/m 40 kN/m 12% 700% | 29 kN/m 53 kN/m 12% 700% |

■ Tear Resistance | ASTM D1004 | 62 N | 93 N | 125 N | 187 N | 249 N |

■ Puncture Resistance | ASTM D4833 | 160 N | 240 N | 320 N | 480 N | 640 N |

■ Stress Crack Resistance | ASTM D5397 | 500 hrs | 500 hrs | 500 hrs | 500 hrs | 500 hrs |

■ Carbon Black Content | ASTM D1603 | 2.0% | 2.0% | 2.0% | 2.0% | 2.0% |

■ Carbon Black Dispersion | ASTM D5596 | For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 | ||||

■ Oxidative Induction Time (OIT) | ASTM D3895 | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. |

■ UV Resistance High Pressure OIT retained after 1600hrs |

ASTM D5885 |

50% |

50% |

50% |

50% |

50% |

Dimensions |

|

|

|

|

|

|

■ Roll Width (m) |

| 7 | 7 | 7 | 7 | 7 |

■ Roll Length (m) |

| 420 | 280 | 210 | 140 | 105 |

|  |