Products Description

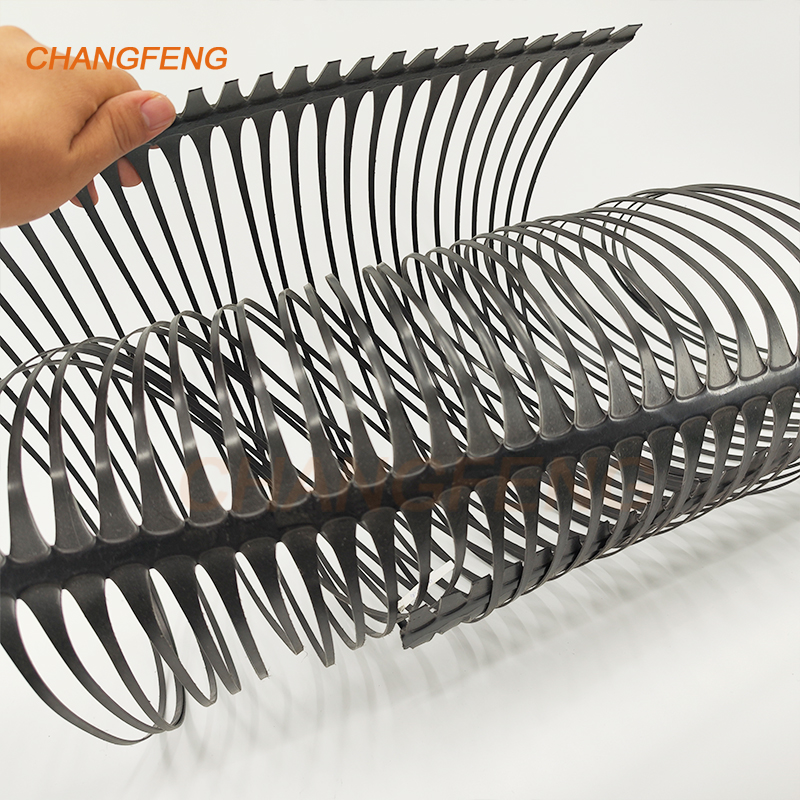

Unidirectional geogrid is a high-performance geosynthetic material designed to provide enhanced reinforcement in soil and aggregate applications. Manufactured from high-strength polypropylene or hdpe, this geogrid features a unique one-dimensional structure that effectively distributes loads and improves stability.

Application:

1. Unidirectional geogrid is used to make foremost inclined foundations: geogrid can shortly enhance the bearing workable of the foundation, manipulate the enchancment of settlement, and correctly distribute the load on a wider sub base layer due to its lateral limiting impact on the avenue base layer, thereby decreasing the thickness of the base layer, lowering engineering costs, shortening the developing period, and extending the provider life.

2. Unidirectional geogrid is used for strengthened asphalt or cement pavement: geogrid is laid at the backside of the asphalt or cement pavement layer, which can restriction the depth of ruts, prolong the fatigue existence of the pavement, and in addition restriction the thickness of asphalt or cement pavement to retailer costs.

3. Unidirectional geogrid is used to toughen river and sea embankments: it can be made into a gabion and used in mixture with the grid to quit the dam from collapsing due to seawater erosion. The gabion has permeability, which can gradual down the have an effect on of waves, extend the existence of the dam, maintain manpower and fabric resources, and shorten the developing period.

4. Unidirectional geogrid is used to deal with landfill sites: geogrids blended with one of a kind geosynthetic assets can effectively cure troubles such as uneven contract of the basis and emissions of derived gases, and maximize the storage performance of landfill sites.

Construction methods

When used for bolstered soil retaining walls, the enchancment approach is as follows:

1. Set up the basis and deliver collectively in accordance to the designed wall system. When the use of precast bolstered concrete panels, they are generally supported on the precast concrete groundwork with a thickness of 12-15cm. Its width shall no longer exceed 30 cm, thickness shall no longer be a top notch deal a lot much less than 20 cm, and burial depth shall now no longer be a complete lot an awful lot much less than 60 cm to stop the have an influence on of basis frost heave.

2. Smooth the wall foundation, excavate and stage in accordance to the layout requirements. Soft soil desires to be compacted or replaced, and compacted to the required density, which ought to barely exceed the fluctuate of the wall.

Properties of PP Uniaxial Geogrid

Properties of HDPE Uniaxial Geogrid

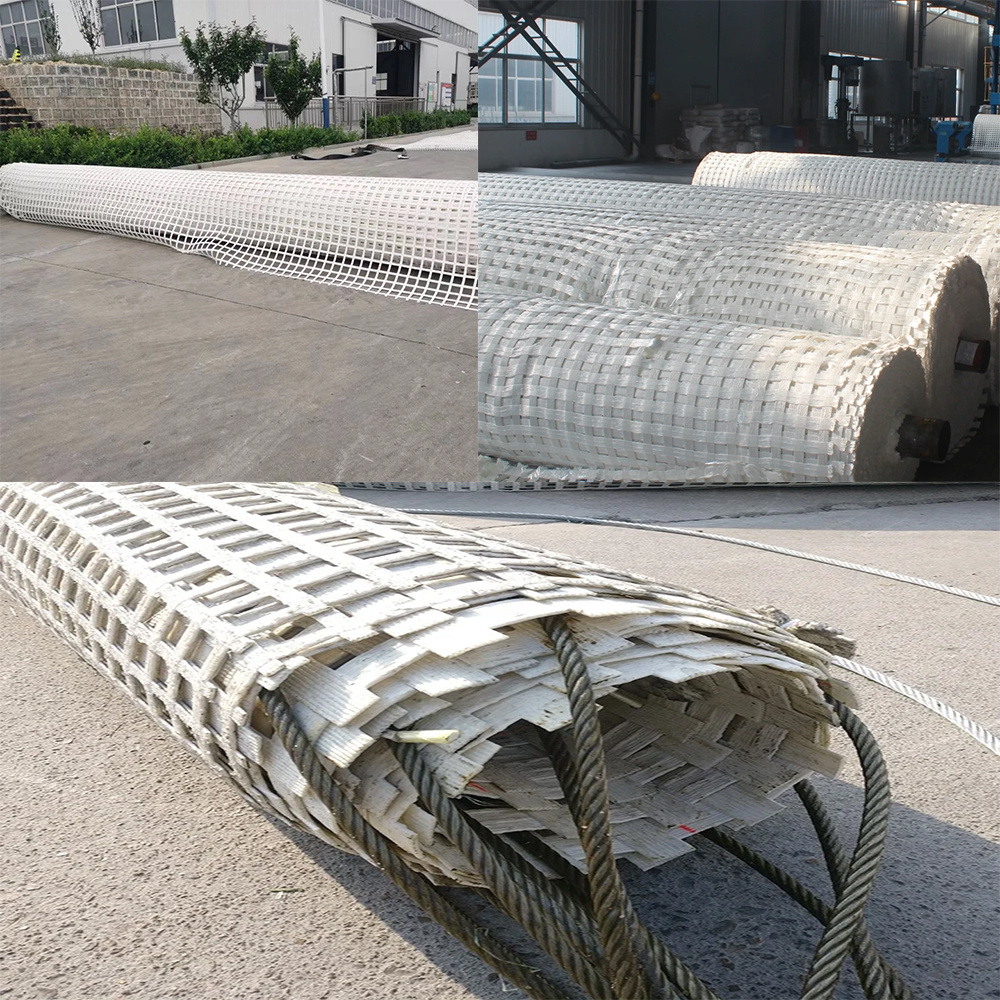

On site shipment