Products Description

Black plastic mulch layer are the most desired ones due to the fact of its excessive overall performance in weed control. While white coloured mulch movies is used to hold the soil temperature low in excessively excessive temperature regions, the silver/black plastic mulch movie is used in Summer excessive temperature pest -prone areas and for melons , veggies and different crops.In addition to these colors, for precise purposes crimson and blue colorations are used to enhance the plant development.

|  |  |  |  |

|  |  |  |

|

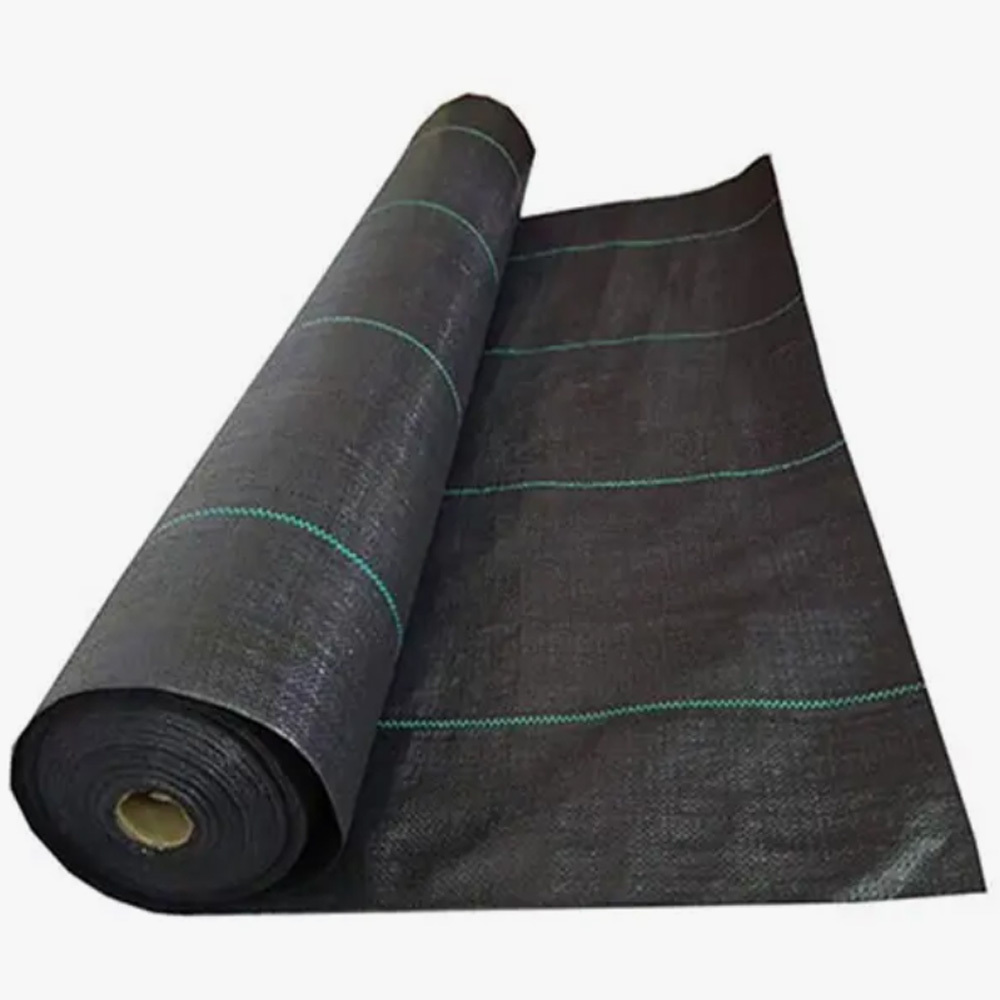

Weed mat,Weed clothing,landscape fabric,a woven polypropylene, it is UV stabilized and water permeable, maintaining your soil under wholesome even as stopping any weeds.The width and size of weed mat can customized,according to customer's requirement,the colour typically is black and green,or make to order.Weeding fabric has UV resistant,corrosion resistance,anti-aging feature,which lets in air, vitamins and beverages to omit via to the soil. Weed mat is extensively used in agricultural production, used in fruit and vegetable planting can have warmness preservation, frost prevention, anti insects, birds, and breathable, waterproof.Of course,weed apparel fundamental characteristic is inhabit the boom of weed,protect the fruit timber or veggies grow.

| Woven Geotextile Technical Specifications (GB/T 17690-1999) | ||||||||

| Item | Specifications | |||||||

| 20-15 | 30-22 | 40-28 | 50-35 | 60-42 | 80-56 | 100-70 | ||

| 1 | Warp breaking strength (kN/m)≥ | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

| 2 | Weft breaking strength (kN/m)≥ | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

| 3 | Longitude and latitude elongation at break %≤ | 28 | ||||||

| 4 | Trapezoidal tear strength (longitudinal force) kN≥ | 0.3 | 0.45 | 0.5 | 0.6 | 0.75 | 1.0 | 1.2 |

| 5 | Burst strength kN≥ | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

| 6 | Vertical permeability coefficient, cm/s | 10-1-10-4 | ||||||

| 7 | Equivalent aperture / mm | 0.08-0.5 | ||||||

| 8 | Mass per unit area / sqm. | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

| Allowable deviation value /% | ±10 | |||||||

| 9 | UV resistance strong retention rate /% | According to customer needs | ||||||