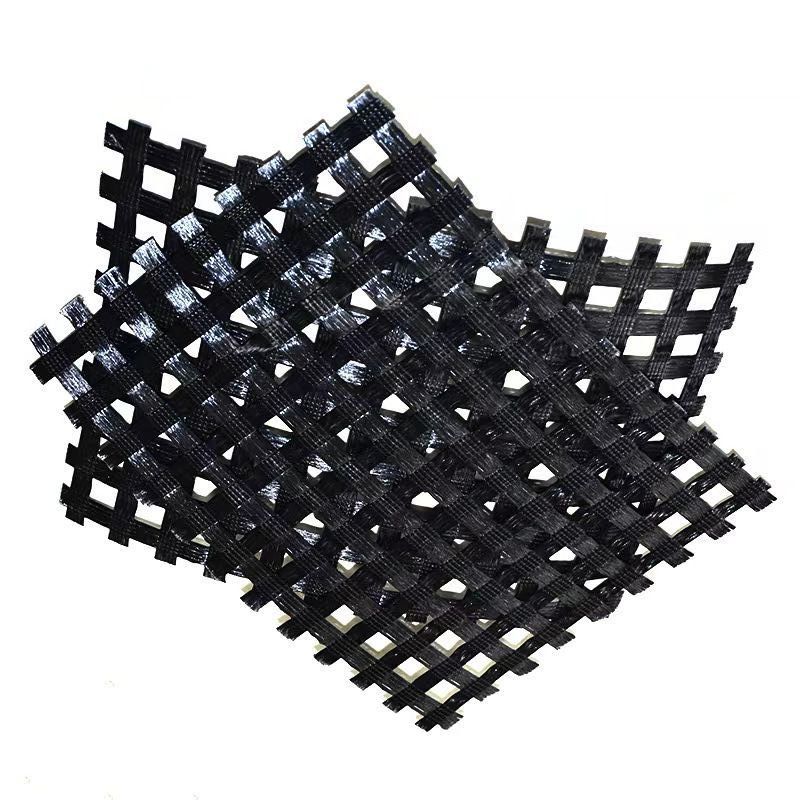

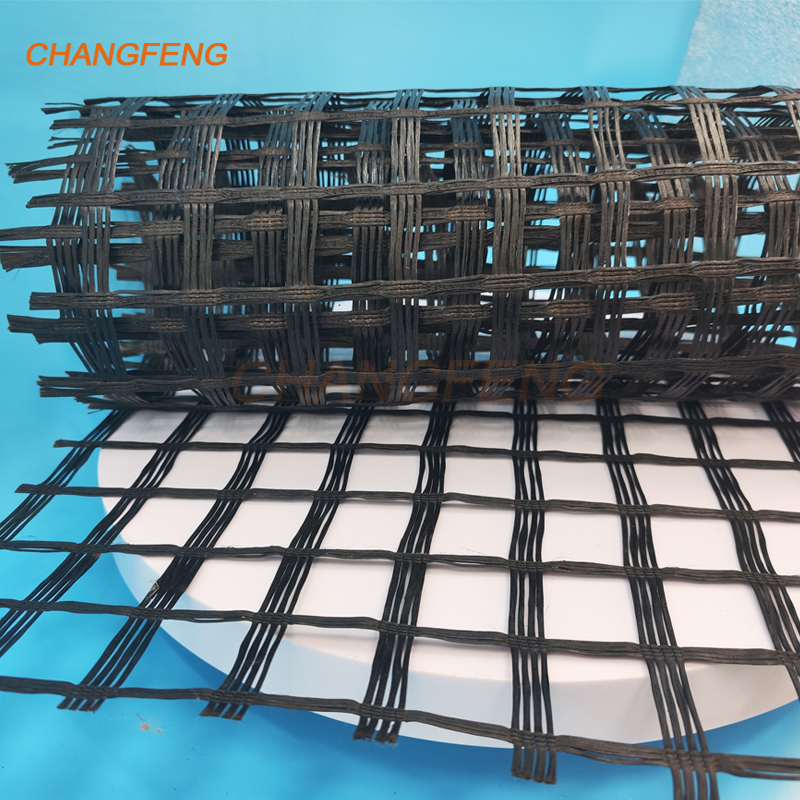

Products Description

Fiberglass geogrid is a variety of aircraft community form fabric that selects extraordinary reinforcement non-alkali fiberglass yarn. It is weaven in to base cloth through the usage of overseas superior warp knitter and adopts warp knitted directional structure, It make full use of yarn electricity in textile, improves its chemical overall performance and makes it have desirable anxiety resistance, tearing resistance and creep resistance and is fashioned by means of incredible modified asphalt coating treatment. It follows comparable and well suited principle, lays stress on its artificial overall performance with asphalt mixture, protects glass fiber base fabric full and enhance carrying resistance and sharing pressure resistance of base cloth so as to make street floor reinforce, to stop toll road damage such as crack and rut from going on and to clear up the trouble that asphalt rode floor is challenging for reinforcement.f alkali resistance and developing historic resistance.

1,fiberglass geogrid have Light weight, excessive tensile strength, excessive modulus, low elongation and correct toughness.

2,Corrosion resistance, no long-term creep, lengthy lifestyles span.

3,Good bodily and chemical balance and suitable thermal stability.

4,Resistant to fatigue cracking, high-temperature music and low temperature shrinkage cracking.

5,fiberglass geogrid can Delaying and reducing crack reflection.

Specification | EGA30-30 | EGA50-50 | EGA80-80 | EGA100-100 | EGA120-120 | |

Mesh size(mm) | 25.4×25.4 Or 12.5×12.5 | |||||

Breaking strength ≥(KN/m) | Warp direction | 30 | 50 | 80 | 100 | 120 |

Across warp | 30 | 50 | 80 | 100 | 120 | |

Elongation at break ≤(%) | Warp direction | 3 | ||||

Across warp | 3 | |||||

Elasticity modulus(GPA) | 67 | |||||

Thermal tolerance | -100~280℃ | |||||

Width | 1~6m | |||||

Notes MD = Machine Direction; TD = Transverse Direction