Products Description

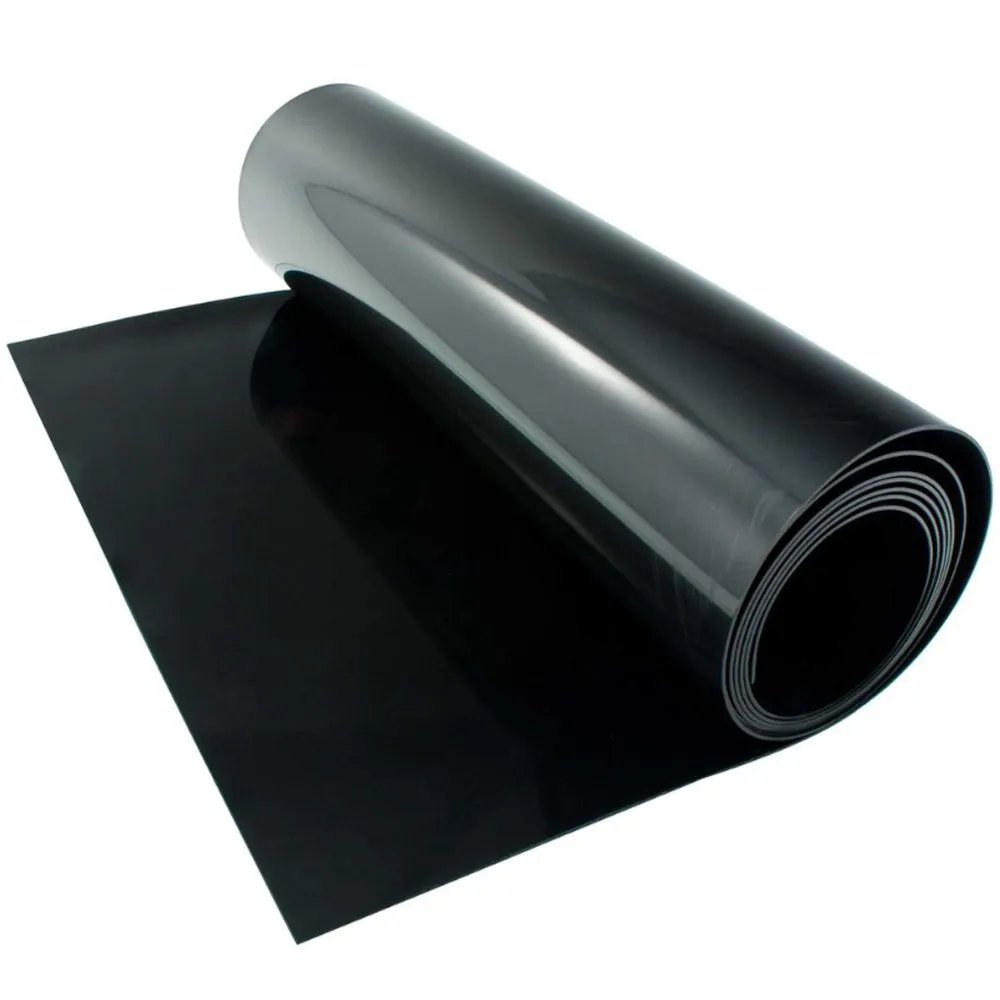

| Name; geomembrane |

| Length; 1-6m |

| Thickness; 0.3 -2 mm |

| Material; HDPE, LDPE, PVC, LLDPE |

| Color; Black, white, blue, customized products can be supported according to customer needs |

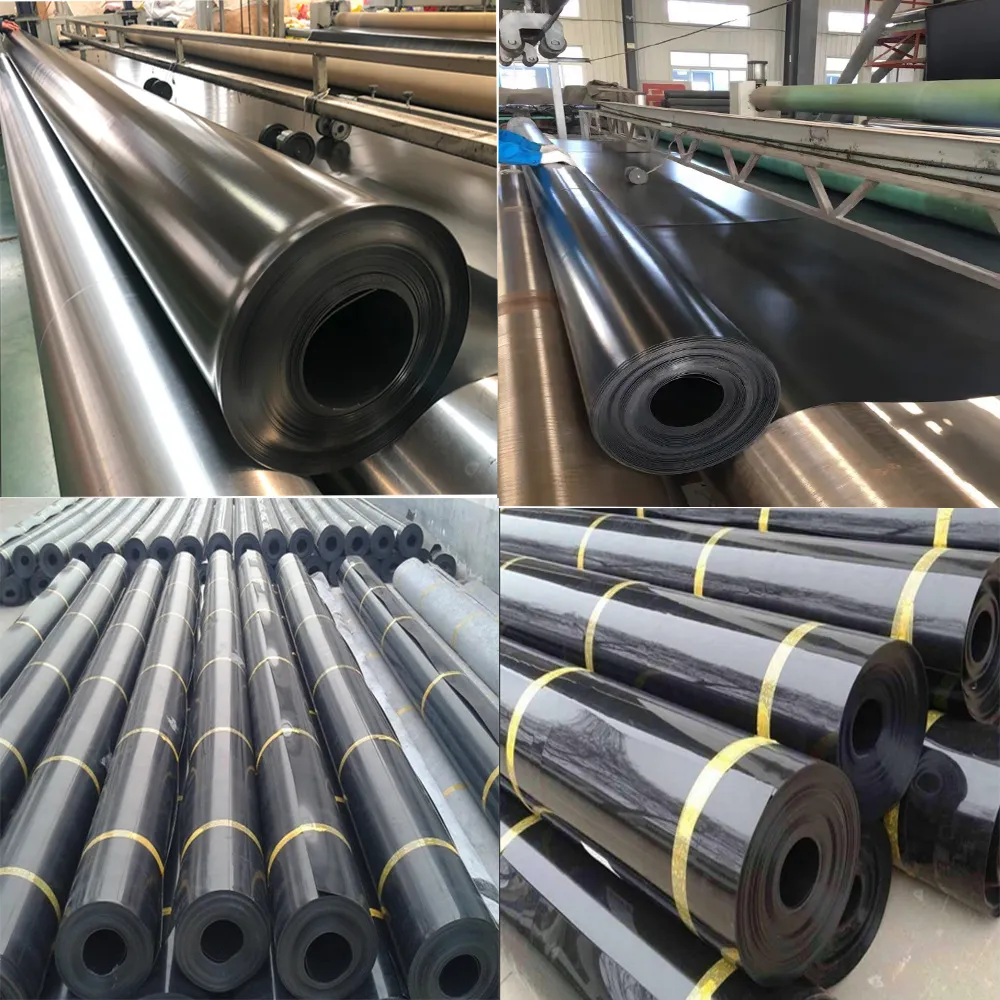

HDPE Geomembrane and pond liner is produced from excessive density polyethylene resin by way of film-blowing process, adding carbon black, antioxidant, anti-aging and UV-resistance component. Now it is the most broadly used merchandise for strong waste containment (such as landfill liners), mining and water containment applications

|  |  |  |  |

- Environmental protection, environmental hygiene (such as rubbish landfill site, remedy of sewage, containment of toxic or unsafe wastes, hazardous warehouse, enterprise wastes, development & explosive rubbish, etc).

- Water conservancy (such as waterproofing, stopping up leak, reinforcement for lake, river, channels, tunnels, dams and reservoirs; vertical wall with core, slope protection, etc.

- Municipal engineering (expressway, subway, underground engineering of building; and liner of roof pool, roof garden's waterproofing, sewage channel, etc)

- Garden (backing & slope safety of synthetic lake, pool, golf course's pond.

- Petrochemicals (liner secondary lining of chemical reeaction tank and savings tank from chemical plant & refinery; seepage manipulate of oil tank from gasoline station

- Mining (backing seepage of washing pond, heap leaching pond, ashery, dissolved pond, credit score pond from the stack and tailing.

- Traffic services (highway basis reinforcement, culvert stopping up leak

|  |

|  |  |

Properties | Test Method | GMSH050 | GMSH075 | GMSH100 | GMSH150 | GMSH200 |

■ Thickness | ASTM D5199 | 0.50 mm | 0.75 mm | 1.00 mm | 1.50 mm | 2.00 mm |

■ Density | ASTM D1505 | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc |

Tensile Properties |

|

|

|

|

|

|

■ Yield strength ■ Break strength ■ Yield elongation ■ Break elongation | ASTM D6693 Type IV

| 7 kN/m 13 kN/m 12% 700% | 11 kN/m 20 kN/m 12% 700% | 15 kN/m 27 kN/m 12% 700% | 22 kN/m 40 kN/m 12% 700% | 29 kN/m 53 kN/m 12% 700% |

■ Tear Resistance | ASTM D1004 | 62 N | 93 N | 125 N | 187 N | 249 N |

■ Puncture Resistance | ASTM D4833 | 160 N | 240 N | 320 N | 480 N | 640 N |

■ Stress Crack Resistance | ASTM D5397 | 500 hrs | 500 hrs | 500 hrs | 500 hrs | 500 hrs |

■ Carbon Black Content | ASTM D1603 | 2.0% | 2.0% | 2.0% | 2.0% | 2.0% |

■ Carbon Black Dispersion | ASTM D5596 | For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 | ||||

■ Oxidative Induction Time (OIT) | ASTM D3895 | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. |

■ UV Resistance High Pressure OIT retained after 1600hrs |

ASTM D5885 |

50% |

50% |

50% |

50% |

50% |

Dimensions |

|

|

|

|

|

|

■ Roll Width (m) |

| 7 | 7 | 7 | 7 | 7 |

■ Roll Length (m) |

| 420 | 280 | 210 | 140 | 105 |

|  |